High-Throughput Immunofluorescence Staining & Immunophenotyping

Biomarkers play a critical role in clinical diagnostics and treatment as well as in drug screening and prognosis. Immunofluorescence and immunophenotyping are just two common techniques used to detect the relative abundance and location of protein biomarkers in fixed cells.

Biomarkers play a critical role in clinical diagnostics and treatment as well as in drug screening and prognosis. Immunofluorescence and immunophenotyping are just two common techniques used to detect the relative abundance and location of protein biomarkers in fixed cells.

Both methods, immunophenotyping and immunofluorescence staining, are often performed manually and require intense optimization and quality control. Automating these protocols on the VANTAGE allowed researchers to control user errors and increase throughput. Because of the unique vertical integration of the platform and tremendous flexibility of the pipetting deck, both assays were able to performed on-deck simultaneously. By using the native Scheduler, researchers were able to run parallel activities and process multiple plates simultaneously, thereby maximizing the throughput of both methods. Overall, automation of immunophenotyping and immunofluorescence protocols on the VANTAGE increased walk-away time while producing high quality results.

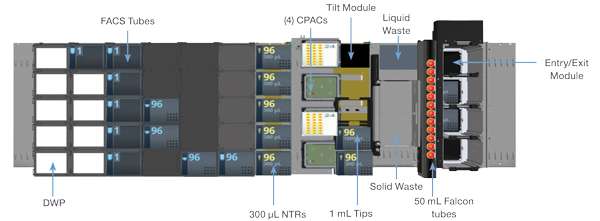

System Deck Layout

Key Features

- Vertical integration through the Logistics Cabinet and Track Gripper minimizes system footprint and enables below-deck integration of the following devices:

(5) Inheco Thermoshakes, (2) Inheco MTEC Controllers, Agilent VSpin, Biotek ELX405US washer/bottles - Deck flexibility and labware capacity is maximized with the Entry/Exit tip and plate shuttling module

- Dynamic scheduling increases efficiency and throughput, allowing up to (5) plates of each assay to be processed in a single run

- Clean integration of chemical exhaust hood

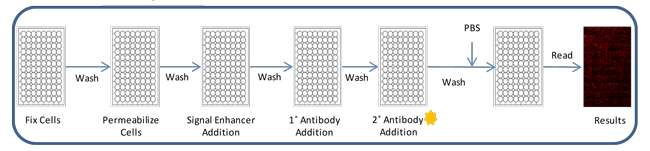

Workflow

Immunofluorescence Staining Protocol

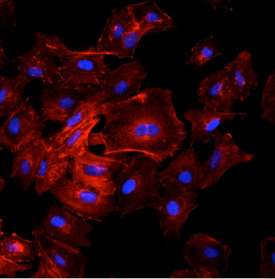

Results

Results

Following fixation on Hamilton Vantage, A549 cells maintained normal morphology. Nuclei and actin staining was even across the wells. Images were taken on ImageXpress Micro, Molecular Devices automated microscope.

Conclusion

Researchers were able to successfully automate both immunophenotyping (not shown) and immunofluorescence assays on the VANTAGE. All the reagents and devices, including cooling station and plate washer, were integrated and performed as expected. Automation on the VANTAGE increased efficiency by allowing researchers to execute the immunofluorescence protocol overnight with no human intervention. Also, productivity was increased whereby five plates were processed in 9.5 hours compared to one plate in 4.5 hours. Of final note, due to the automation of the long and strenuous process, researcher fatigue associated with manual processing was greatly reduced.