Seeing is Believing: Reproducible Proteomic Studies

LISTED UNDER:

For scientists, the field of proteomics has always been a double-edged sword. On one hand, technologies such as 2-dimensional gel electrophoresis (2-DE) capture a vastly improved picture of protein expression in action. But when others try to reproduce the experiment? The findings can suddenly appear blurry.

For scientists, the field of proteomics has always been a double-edged sword. On one hand, technologies such as 2-dimensional gel electrophoresis (2-DE) capture a vastly improved picture of protein expression in action. But when others try to reproduce the experiment? The findings can suddenly appear blurry.

What has stood in the way of predictable results are the many manual steps required for quantitative analyses. After nearly four decades, the technology remains a series of tasks for laboratory staff, each subject to human variation and error. Compounding this is the instability of proteins and patterns of cell expression. Many great insights have come from this era of proteomics, but much has also been lost in translation.

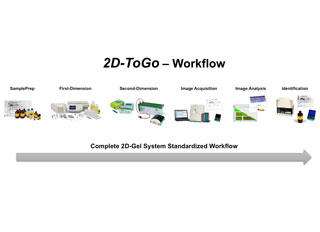

Success moving forward comes down to clarity and reproducibility. Stefan Lehr, Ph.D., head of proteomics at the German Diabetes Center in Düsseldorf, has, with his colleagues, created a workflow to do just that. It’s called 2D-ToGo— an industry-specific methodology designed to improve the reliability of the most error-prone steps in 2-DE quantitative analyses.

Along with standardizing operations, Lehr’s team drew together the latest in instrumentation and consumables, ensuring that 2-DE scientists are speaking the same language and seeing the same picture, with results. The potential to increase industry efficiency is huge. It streamlines training staff in proteomics and decreases the number of re-runs due to results failing to match.

Before advocating for the new workflow, the researchers knew 2D-ToGo needed testing. To assess reliability, the 2D-ToGo protocol was performed on 18 gels and analyzed across three different labs using a standard E. coli sample. Despite the changes in location, results from each lab closely matched each other. The correlation coefficients were found to be between 0.91 and 0.95. The results prove that the many variables in 2-DE can be tamed, breathing new life into this venerable technique and the proteomics community.

So, what are the 2D-ToGo specifics? It starts with sourcing the right equipment and consumables. Lehr credits much of 2D-ToGo’s reproducibility to product advancements in each of the two dimensions for differentiating proteins. The team uses the PROTEAN i12 IEF system in the first dimension and Criterion TGX Any kD Stain-Free Precast Gels in the second, both from Bio-Rad Laboratories.

During the first dimension, isoelectric focusing (IEF) is used to distribute the proteins according to their electric charge. A current is run through the gel, which compels the proteins to find the unique point at which their charge will stand at neutral. The process is not automated, and as a result IEF is a major source of spot-to-spot variability across 2-DE gels.

The PROTEAN i12 IEF system cuts out much of the variability that plagued earlier technologies. It enables researchers to independently control and monitor both the current and voltage profile of each immobilized pH gradient (IPG) strip during separation. In one run, this allowed Lehr and his team to evaluate whether all sample/strip profiles (e.g. 12 samples) achieved a threshold separation performance. Samples that didn’t meet the ideal profile during the run could be identified and often “rescued” by adjusting the strip-specific separation parameters. If the team had used an IEF system, without the ability to independently control and monitor the strips, problems with one sample/strip would have negatively impacted all strips running on the IEF cell.

The process behind the second dimension— sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE)— is another major source of gel-to-gel variability. Uneven polymerization during gel casting can cause distortions within the gel matrix, which in turn distorts the protein spot pattern. Visualizing those results— another manual process— introduces further unpredictability.

Using standardized stain-free precast gels eliminates the variability of handcasting SDS-PAGE gels. Composed of proprietary gel and buffer chemistries, the stain-free precast gels contain chemicals that bind to tryptophan molecules in the proteins as they migrate. With a stain-free enabled imager, such as the ChemiDoc MP or Gel Doc EZ imaging system from Bio-Rad, it was able to visualize the gels without staining them. This eliminates the variability introduced by manually staining. And, because the stain-free gels can be imaged in less than five minutes, the stain-free method also saves two to three hours over traditional methods.

Reproducibility is a cornerstone of modern science, but despite decades of progress, it has remained one of the greatest weaknesses in the field of proteomics. The success of 2D-ToGo, achieved with the latest 2DE technology, shows variables and inconsistencies are finally being overcome and offers the ability to get down to the real science.